- JOHN RUSKIN -

- JOHN RUSKIN -

QUALITY MANAGEMENT

Quality is the basis of our service. For us, quality management means acting with foresight. That is why we ensure quality at every stage of our production and exclude possible errors in advance. This is to benefit our customers, expand our working relationship with our suppliers and optimise processes between departments in-house. We apply these guiding principles by integrating a quality management system as per EN 9100:2018 and EN ISO 9001:2015.

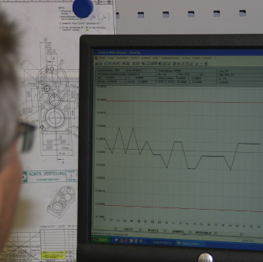

QUALITY, TEST TOOL OUTPUT

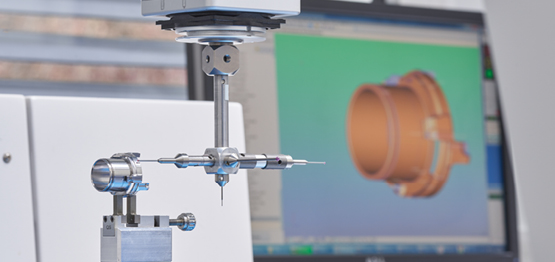

COORDINATE-MEASURING MACHINE

All quality-relevant processes are controlled based on the PDCA method:

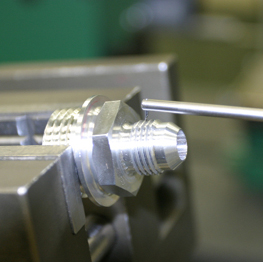

QUALITY ASSURANCE

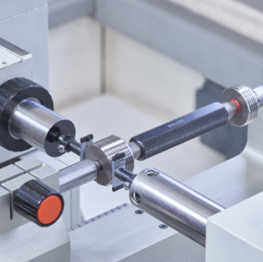

The goals and strategies formulated in the quality policy and the declaration of commitment provide direction for Müller Präzisionsteile GmbH’s business activities. The Quality Assurance department monitors these requirements in daily practice. Besides ultra-modern measurement instruments and a laboratory, we use more than 3,500 movable test devices, which are subject to their own test device monitoring with a Zeiss ULM. Our Quality Assurance team comprises experienced specialists who are able to draw on a wide variety of equipment.

> Technical features

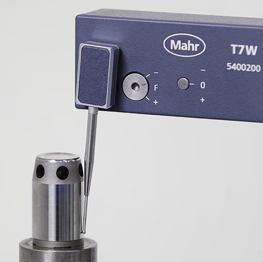

Make: Mahrshaft SCOPE 750 Plus – CNC-controlled optical wave measurement system up to 750 mm in length and 120 mm in diameter

Make: Mahr Perthometer

Make: Mitutoyo SJ-201, MahrSurf SD 25 Perthometer S 2

COORDINATE-MEASURING MACHINES

| 1 universal measurement centre | 1 universal measurement centre | 1 universal measurement centre | 1 universal measurement centre | 1 optical/tactile measurement centre | |

|---|---|---|---|---|---|

| Make | Zeiss | Zeiss | Zeiss | Zeiss | Zeiss |

| Type | Prismo Navigator 10 | Prismo 7 VARIO | Accura 7 | Prismo Navigator 7 HTG | O-Inspect |

| X-, y- and z- axis | 1,200 mm, 2,400 mm, 1,000 mm | 900 mm, 1,200 mm, 700 mm | 900 mm, 1,500 mm, 700 mm | 900 mm, 1,200 mm, 650 mm | 500 mm, 400 mm, 300 mm |

| Measurement uncertainty | U1 = (1.5 + L/350) µm sensor system: Vast Gold software: Calypso with rotary table RT-AB 400 | U1 = (2.0 + L/350) µm U3 = (2.3 + L/300) µm sensor system: Vast Gold (measuring scanning head) software: Calypso | MPE = (1.7 + L/333) µm sensor system: Vast Gold software: Calypso | MPE = (1.4 + L/333) µm sensor system: Vast Gold software: CALYPSO rotary table RT05 400 Gear Pro involute, CNC curve | MPE = (1.6 + L/250) µm (tactile) MPE = (1.9 + L/150) µm sensor system: Vast xxt + DotScan software: CALYPSO |

Make: Mahrform MMQ 400

For non-destructive crack testing (magnetic-particle method and dye penetration process)

By IQS (including initial-sample testing module)

Make: Zeiss ULM; measurement uncertainty: U1 = 0.4 μm

Make: Eltrotec; model: PKF

Make: Leica MZ 6 and Zeiss

> 700 movable testing devices, such as dial gauges and micrometers

> 3,500 testing devices, such as go-no gauges and thread ring gauges

Make: Stotz

CERTIFICATES

Identification transfer agreement

Certificate for identification transfer of materials and

manufactured items for pressure equipment as per

Directive 97/23 EC and AD 2000 technical info sheets